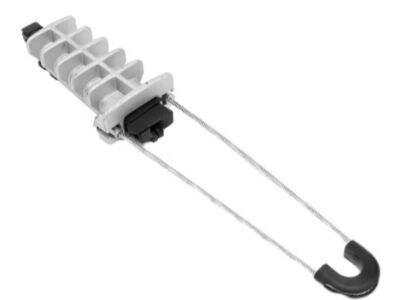

We have been talking a lot about suspension clamp coatings, as they play a very important role in the surface treatments for staying longer outside. This brings us to the first point of why surface treatment is so critical for Dingcheng spring tension clamps Coatings used outdoors.

Significance of the Surface Treatment on the Coating of Suspension Clamps

Surface treatment also involves coating the surface of a material to improve its characteristics. Surface treatment is an important process to protect the metal of suspension clamp coatings from rust, corrosion & other damages due to environmental exposure. In the absence of effective surface treatment, this coating may wear out soon which once again leads to corrosion susceptibility in the metal.

The Durable Finish Outdoor Application Surface Treatment

Usage of suspension clamp coatings outside causes them to be in direct contact with harsh weather conditions like rain, snow, wind, and sunlight. They break the surface and as time goes on, can deteriorate the coating down to weaken the metal beneath. Surface treatment creates a layer between the coating and the environment, preventing moisture and other compounds from entering into the surface. This keeps the coating intact and helps it to last longer.

Main Causes of Surface Treatment on Suspension Clamp Coatings

With the suspension clamp coatings, we can enhance lifespan by applying surface treatment over them. A surface treatment protects the inner workings from environmental fallout, like rust and corrosion that can wear away at the coating faster than intended. When Dingcheng wire tension clamp coatings are properly treated, they will last longer and perform outdoor better.

Advantages of Suitable surface treated for outdoor utilization

Improved Durability, Aesthetic Appearance & Performance for Suspension Clamp Coatings Surface Treatment The purpose of surface treatments is to prevent the coating from becoming damaged, and therefore keep the metal solid for much longer. Surface treatment further enhances the appearance of your coating giving it a more aesthetically pleasing and professional look.

The Importance of Surface Treatment for Suspension Clamp Coatings in Outdoor Environment

Surface treatment is very important to the rust-proof performance of suspension clamp coatings in outdoor. A protective coating or sealant can shield the coatings from environmental degradation, helping them to last longer. Good surface treatment increases the life cycles of those coatings on suspension clamps and also preserves their appearance and function. Consequently, surface treatment for Dingcheng pg clamps coatings should be set at the front line when using outside.

Table of Contents

- Significance of the Surface Treatment on the Coating of Suspension Clamps

- The Durable Finish Outdoor Application Surface Treatment

- Main Causes of Surface Treatment on Suspension Clamp Coatings

- Advantages of Suitable surface treated for outdoor utilization

- The Importance of Surface Treatment for Suspension Clamp Coatings in Outdoor Environment